SunLuxe utilizes a quality system procedure that effectively prevents the shipment of non-compliant material. The quality system is based on the industry recognized standard of ISO 9001.

| 1.) Raw Material Control: SunLuxe employs controls in place to assure raw material received is in conformance to specification. All raw materials are inspected and formally noted during the inspection status. All specification instructions outline the characteristics to be inspected and criteria for acceptance. |

|

|

2.) Part Variation / Calibration: SunLuxe utilizes testing equipment controlled by item identity number and controlled by a documented system with archived records. The calibration frequency standards used at SunLuxe meet PRC national standard. |

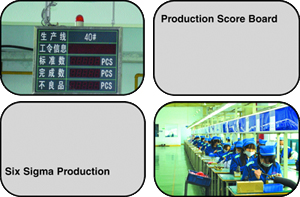

| 3.) In-house TOOLING AND Production: Our goal is to deliver Zero defects (DPMO) to our vendors. We focus our qualification procedures on optimizing and standardizing the manufacturing process. Change from the established qualification process is unacceptable. |

|

|

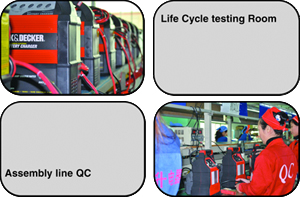

4.) SAFETY AND RELIABILITY TESTING: Our testing center has all required equipment in place to perform safety / endurance / reliability tests. SunLuxe has provisions to record failures, and formally investigate them |

| 5.) SUPPLIER PRODUCTIVITY: SunLuxe utilizes a rating system to communicate metrics and goals for the year and performance toward those goals. The criteria includes: Quality, Productivity, Service Level, and Spend. |

|

|

6.) QUALITY AUDITS: Our goal is to deliver Zero defects (DPMO) to our vendors. We focus our qualification procedures on optimizing and standardizing the manufacturing process. Changes from the established qualification process are unacceptable. |